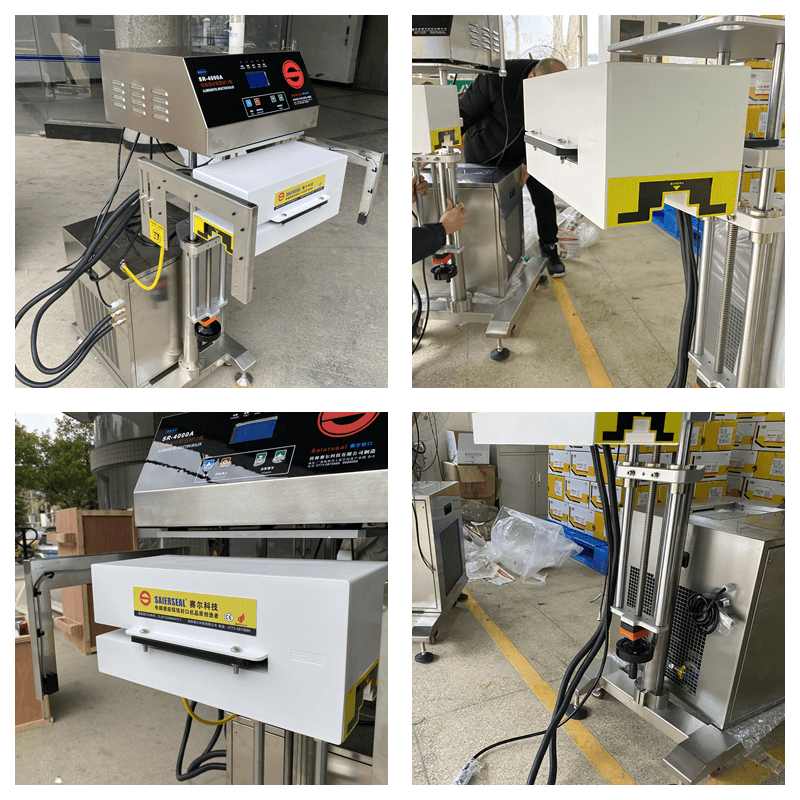

High Speed Water Cooled Induction Sealing Machine for Pharmacy Filling line SR-4000A

Features:

1. The fuselage is made of 304 stainless steel, with protection grade of IP51, in line with GMP standard.

2. The inductor adopts ABS material standard mold design.

3. Three-track three-dimensional magnetic field induction mode.

4. Intelligent control system.

5. Adopt spiral sliding lifting group to adjust the sealing position of the bottle body (maximum lifting stroke is 420 mm).

6. The whole machine has good anti-electromagnetic interference performance.

7. Fully enclosed module circuit, reliable performance, greatly extend the operating life of the equipment.

8. Double water pump drive circulating heat dissipation, greatly enhance the heat dissipation intensity.

9. Intelligent electrical protection system (overvoltage, overcurrent, overheating, water shortage, blockage).

10. Accurate control of magnetic and thermal strength.

Built-in stabilized power supply, constant output of auxiliary power.

12. Adopt the design of silent machine operation.

Optional parts.

*PLC touch screen with seal counting fuction, Optical-electro sensor detect, pause during bottle missing or jam, auto operating after re-set .

* The conveyor and missed foil cap rejector.

Advantages:Can be against moisture,erosion,dust and mangetism,minimizes maintenance.

Within 15 minutes to replace new CPU(2kg),any problems of machine can be solved.

Product: for pesticide, tablet & capsule, foods, cosmetic, lubricant &oil packaging etc. Plastic bottle and glass bottle sealing.

Bottle diameter: 15mm-75mm (custmized to 220mm )

Sealing speed: 200 bottles per minute(diameter 30mm for example)

Applicable bottle height: 0-490mm

Power: 4000W

Voltage: 50/60Hz, 220V

Induction head size: 450mm*200mm*90mmBody material: SUS304 stainless steel

Machine weight: 85Kg

Packaging size: 600mm*560mm*720mm

& 930mm*830*280mm

Online feedback

Feedback to us, we will contact you shortly. (The following * are mandatory)

- PREVWater-cooled Sealer SR-4000X

- NEXTNo record