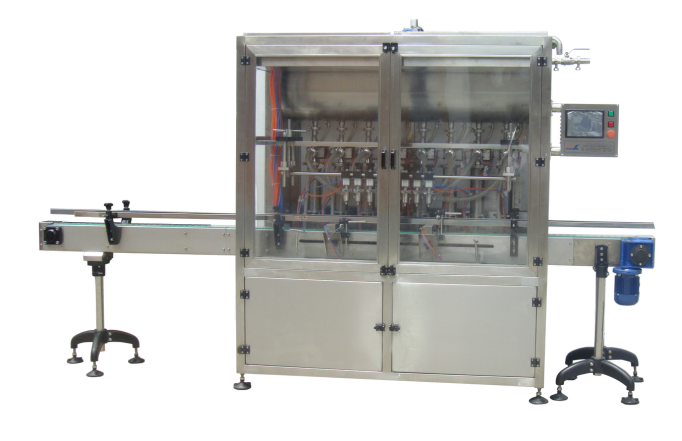

I.1. The machine name:

SR-8A 8-heads automatic filling machine

1.1 Overview of this machine:

These series filling machine is researched and developed by our company with absorbing advanced technology of the abroad, and with so many years of production experience. The machines adopt piston measurement, integrating electric control and pneumatic control. Its electrical and pneumatic components are world-famous products, and it is controlled by PLC. with compact structure and reasonable design. It has such characteristics as reliable performance, precise filling steady, strong adaptability and easy to operation and repair.

1.3 Main parts list:

|

NO. |

Name |

Brand |

|

1 |

PLC |

Nandaaotuo |

|

2 |

Touch screen |

Tai wan WEINVIEW |

|

3 |

frequency changer |

Sanjing |

|

4 |

switching power supply |

OMRON |

|

5 |

pneumatic component |

Taiwan AirTAC |

|

6 |

Sensor |

OMRON |

|

7 |

Motor |

Beijing VTV |

IV. After Service:

u Installation: Our Company will fix and test the machine well enough before delivery. At the same time, your company operators can go to our factory and our technicians will teach them how to install, operate and maintain the machine. If you need our technicians to do fixing, testing or servicing abroad, you need to do with correlative charges.Please pay $50 per day to technician.

u Our machine is guaranteed for one year in which we will supply you with spare parts and services free of charge, man-made damage as well as the delivery cost of the spare parts excluded. When you have problems in process, please feel free to contact our technicians.

Ø The world-famous electrical and pneumatic components are adopted, so the machine will be stable and reliable and could be used with a low failure rate and long service life

Ø The part of machine which touches product are mainly made by the high-quality stainless steel, which makes dismantling, assembling and cleaning more convenient. What’s more, it is in full compliance with food hygiene requirements;

Ø Adjustment of filling volume and filling speed is simple. There is no filling when the bottle doesn’t exist. Liquid level controls filling automatically. It has a nice appearance.

Ø It is adaptable. Without changing elements, bottles of different shapes and sizes can be adjusted and replaced quickly.

Ø Filling mouth with anti-drip device ensure that there is no drawing, no dripduring filling.

It is widely used for filling various kinds of the liquid and semi-liquid without granules, such as shampoo, detergents etc.

Power supply: 220V/50Hz

Power: 2 KW

Air pressure: 0.4-0.6Mpa

Material applicable: car oil

Filling range: 50-500ml

Filling precision: ≤±1.5 %

Filling speed: 2000-2500bottles/h for 500ml

Weight: 600k

Online feedback

Feedback to us, we will contact you shortly. (The following * are mandatory)

- PREVNo record

- NEXTAutomatic labeling machine